TriSolve Plastic Ancillary Solutions

Sise M.E.S Production Monitoring

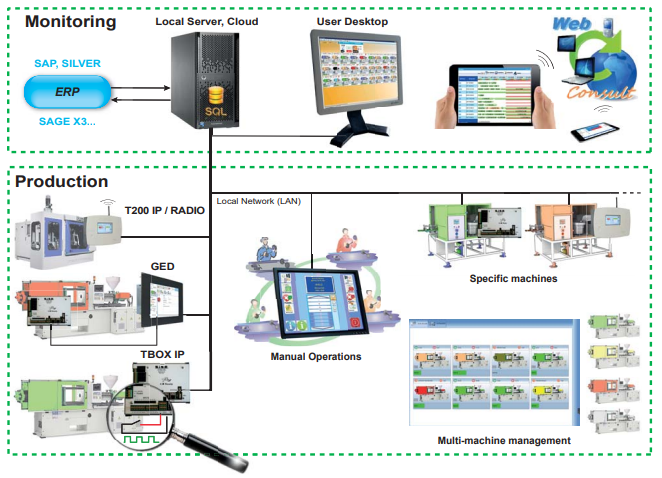

The M.E.S. Cycle Production Monitoring system offers real-time oversight of plastic production processes, quality control, and traceability, as well as the display of indicators to enhance Overall Production Effectiveness (OPE) and Overall Equipment Effectiveness (OEE).

M.E.S. Cycle provides immediate insights from various workshop types. Its integrated modules, including planning, staff assignment, and tool and machine management, collaborate to optimise production. Utilising barcode reading and table archiving ensures traceability of all produced parts.

Standard features of M.E.S. Cycle include monitoring aspects such as tool and machine maintenance, and planning; management features covering production orders, materials, operator actions, and shift changes; and analytical tools for assessing results by shift, production order, and generating custom reports.

M.E.S also offers optional specialised modules:

- ORH Module: Optimizing Human Resources to calculate real-time operator workload and attendance time.

- OM Module: Facilitating manual processing operations for assembly and sorting workshops.

- Energy Module: Providing real-time energy consumption data for each machine or machine pool, calculating consumption per production order or part, and issuing warnings about subscription limits.

- SPC Module: Monitoring control charts for each part.

- Material Consumption Module: Tracking requirements and consumption per production order, material, or machine over a specified period, including entering material batch numbers.

- Web Module: Enabling managers to access a Cycle Web server, check machine pool status using a PC, tablet, or smartphone.

- Barcode Reading Module

- Label Printing Module